Mastering In-Mold Decorations: Techniques, Fads, and Best Practices for Optimal Results

In the world of manufacturing, the art of in-mold decorations stands as a pivotal aspect of product design and manufacturing. As industries continuously seek cutting-edge methods to enhance visual charm and performance, grasping the complexities of in-mold decors has become a critical capability. From selecting the right materials to integrating sophisticated style fads, the journey in the direction of accomplishing ideal lead to this domain is multifaceted. By delving right into the strategies, fads, and ideal methods that underpin successful in-mold design processes, companies can unlock a realm of opportunities that not just elevate the aesthetic attraction of their items but additionally streamline production efficiency and strengthen customer engagement.

Product Choice

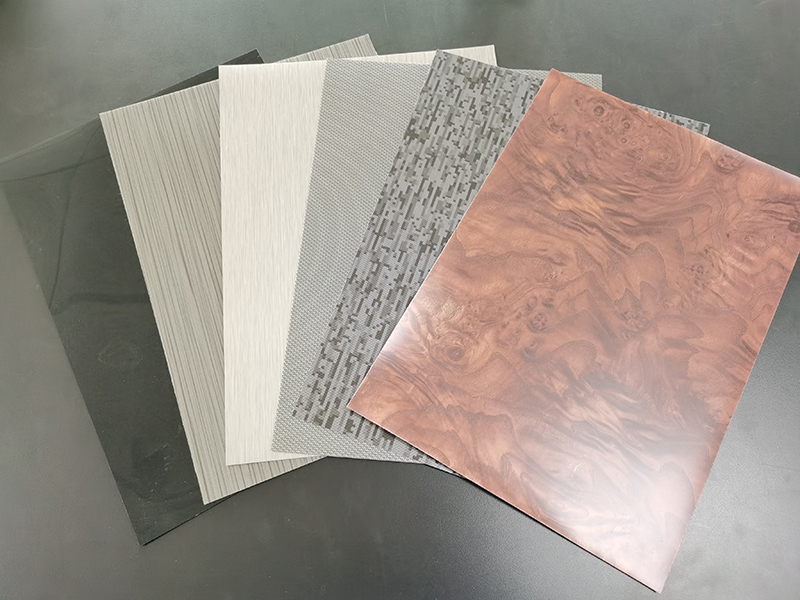

Product choice is an important aspect of understanding in-mold designs, as it straight affects the top quality and longevity of the final item. When selecting products for in-mold decorations, it is essential to think about elements such as compatibility with the molding procedure, the desired visual outcome, and the environmental problems the item will certainly face.

Furthermore, products with high warmth resistance are favored for in-mold decors, specifically for products that will be exposed to raised temperature levels throughout their lifecycle. By carefully choosing the ideal product for in-mold designs, producers can boost the general high quality and sturdiness of their items, satisfying the expectations of both end-users and clients - In-Mold Decorations.

Design Innovation

A necessary variable in progressing the field of in-mold decorations is the continuous expedition and execution of design development techniques. Layout technology plays a critical duty in improving the aesthetic appeal, functionality, and total quality of products produced using in-mold design processes. By incorporating cutting-edge style components, makers can differentiate their items in the marketplace, draw in customers, and stay ahead of competitors.

One of the key facets of design advancement in in-mold designs is the combination of elaborate patterns, textures, and graphics that were formerly testing to achieve with standard decor methods. Advanced modern technologies such as 3D printing and electronic style tools enable designers to create complicated and comprehensive layouts that can be perfectly moved onto molded parts. In addition, making use of vibrant colors, metal finishes, and unique effects like gloss or matte structures can further raise the aesthetic appeal of in-mold embellished items.

Additionally, layout development prolongs past visual appeals to incorporate practical enhancements such as ergonomic forms, incorporated features, and customizable elements that accommodate certain customer needs. By accepting style innovation, manufacturers can open brand-new possibilities for product, personalization, and creativity differentiation in the competitive landscape of in-mold designs.

Production Performance

Reliable manufacturing processes are crucial for converting the cutting-edge styles developed in the area of in-mold designs into top notch finished products that satisfy market needs and customer assumptions. In the realm of in-mold decors, manufacturing effectiveness encompasses numerous vital elements that contribute to the total success of the manufacturing procedure.

In addition, carrying out automation and robotics in the assembly line can dramatically enhance efficiency by simplifying recurring jobs and decreasing the margin of error. Automation not just speeds up the manufacturing process yet likewise boosts precision and repeatability, leading to a much more top notch and uniform output. Embracing lean production principles, such as just-in-time stock monitoring and waste reduction techniques, can additionally boost manufacturing efficiency by lessening downtime and maximizing resource usage. Generally, an all natural approach to production effectiveness is paramount in maximizing the potential of in-mold design methods and attaining ideal lead to the affordable market landscape.

Quality Assurance Actions

What are the vital techniques for making certain rigorous top quality control procedures in the realm of in-mold decorations? Quality control measures are critical in in-mold decor processes to ensure the production of perfect and high-grade ended up items. Get the facts One crucial approach is the execution of rigorous assessment procedures at every stage of the manufacturing process. This involves performing extensive visual evaluations, dimensional checks, and shade consistency analyses to identify any kind of flaws or disparities early on.

Making use of innovative innovations such as automated evaluation systems can additionally enhance the quality assurance procedure by offering exact and reputable information for evaluation. These systems can spot blemishes that might be missed out on by hand-operated assessments, therefore improving general item top quality and uniformity.

Normal training and growth programs for staff members included in the in-mold decoration process can additionally add to preserving top notch standards. By enlightening staff on finest methods, top quality expectations, and the home relevance of attention to information, firms can foster a culture of quality awareness throughout the company.

Customer Charm

To boost the bankability of in-mold decor items, catering and understanding to consumer preferences play an important function in identifying their charm and success. Consumer appeal in in-mold decors is influenced by different elements, including design appearances, shade selections, durability, and overall performance. Consumers are increasingly looking for individualized and special items that show their uniqueness and style. Using customization options such as personalized layouts, shade variations, and textural components can substantially improve the allure of in-mold decor items.

Conclusion

In-mold designs supply a site functional and effective way to enhance item aesthetics. Understanding in-mold designs needs a holistic technique that takes into consideration all elements of the manufacturing procedure to ensure success.

In the world of production, the art of in-mold decors stands as a crucial facet of product style and manufacturing. Layout technology plays a vital function in improving the visual allure, functionality, and total high quality of items manufactured making use of in-mold decor processes.One of the key facets of design development in in-mold designs is the integration of detailed patterns, textures, and graphics that were previously testing to accomplish with standard decor methods.Reliable production procedures are essential for converting the innovative designs established in the area of in-mold decors right into premium ended up products that meet market demands and consumer assumptions. Using customization options such as individualized designs, shade variations, and textural aspects can considerably improve the appeal of in-mold decor items.